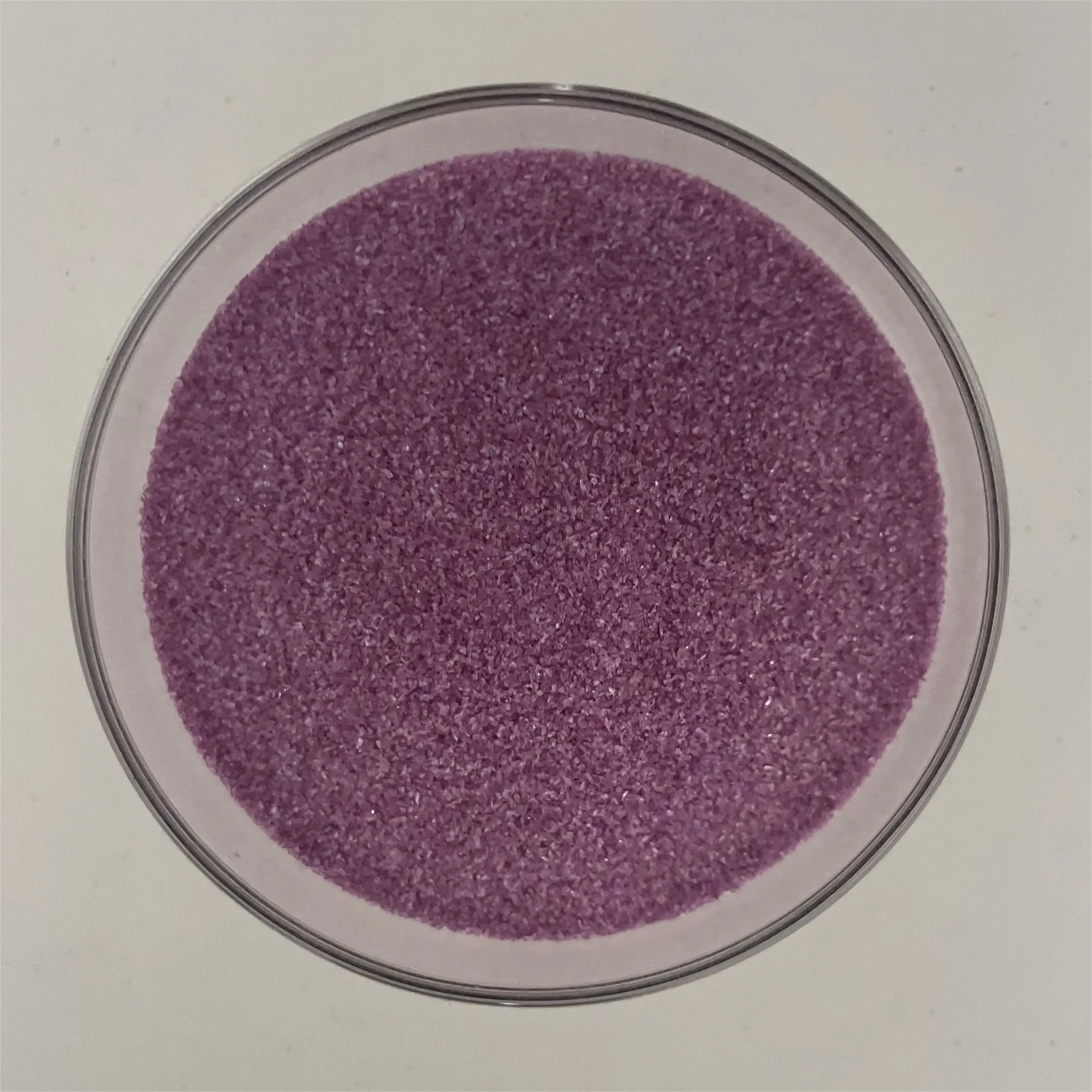

F120 High Chromium Pink Fused Alumina

Pink fused alumina is mainly made of alumina powder, added chromium oxide, and melted at high temperatures. It has the advantages of high hardness, high toughness and high wear resistance. Pink fused alumina is suitable for processing workpieces with high smoothness requirements, such as quenched steel, alloy steel, precision measuring tools, and instrument parts with high toughness.

We provide all specification of white fused alumina, pink fused alumina and brown fused alumina and can customize products according to your requirements. Welcome consulting.

The main raw material of pink fused alumina is aluminum oxide, added chromium oxide, and is melted at high temperature. It is pink or purplish red, with a hardness similar to that of white fused alumina, and higher toughness than white fused alumina. It has characteristics such as high hardness, high toughness, high wear resistance and high stability. When used for processing materials with high toughness, its processing efficiency is higher than white fused alumina, and the surface smoothness of the workpiece is also good. The grinding tools made from pink fused alumina have good durability and high processing cleanliness.

Pink fused alumina our company produced have good crystallinity, pure color, few impurities, uniform particle size composition, low magnetic content, high bulk density, and high toughness.

Pink fused alumina is suitable for processing workpieces with high smoothness requirements, such as quenched steel, alloy steel, precision measuring tools, and instrument parts with high toughness.

According to the different chromium content, it can be divided into three types: low chromium pink fused alumina (chromium content:0.2-0.45%), medium chromium pink fused alumina(chromium content:0.45-1.0%), and high chromium pink fused alumina (chromium content:1.0-2.0%).

Basic Info

| Product Name | Pink fused alumina | |||

| Appearance | Pink grain, pink powder, purplish red grain, purplish red powder | |||

| Al2O3 Content | High chromlum:≥96.5%,medium chromlum:≥97.8%, low chromlum:≥98.5% | |||

| Cr2O3 Content | High chromlum:1.0-2.0%,medium chromlum:0.45-1.0%, low chromlum:0.2-0.45% | |||

| Moh's Hardness | ≥9.0 | |||

| Knoop hardness | 2200-2300 kg/cm3 | |||

| Bulk Density | 1.40-1.95g/cm³ | |||

| Particle Density | 3.95-4.0g/cm³ | |||

| Melting Point | 2050℃ | |||

| Refractoriness | 1800℃ | |||

| Place Of Origin | Shandong, China | |||

| Model | PFA | |||

| Granularity Range | F4-F220 | |||

| Usage | Sandblasting, polishing, abrasives, refractory materials | |||

| Application Area | Metal processing, ceramic manufacturing, glass processing, precision mechanical processing, grinding tool manufacturing | |||

| Package | 25 kg/bag and ton bag, plastic woven bag with plastic bag inside | |||

| Production Capacity | 20000 ton/year | |||

| MOQ | 500 kg | |||

Technical Index

| Chemical Composition Grit Range | Low Chromium | Medium Chromium | High Chromium | ||||||

| AL2O3(%) | Cr2O3(%) | NA2O(%) | AL2O3(%) | Cr2O3(%) | NA2O(%) | AL2O3(%) | Cr2O3(%) | NA2O(%) | |

| F12-F80 | ≥99.00 | 0.2-0.45 | ≤0.40 | ≥98.20 | 0.45-1.00 | ≤0.45 | ≥97.40 | 1.00-2.00 | ≤0.45 |

| F90-F150 | ≥99.00 | ≤0.40 | ≥98.20 | ≤0.50 | ≥97.00 | ≤0.50 | |||

| F180-F220 | ≥98.50 | ≤0.50 | ≥97.80 | ≤0.60 | ≥96.50 | ≤0.60 | |||

Trade details

| MOQ | 500 KGS |

| Payment | 30% as deposit, and balance paid before shipment |

| Place of origin | Shandong, China |

| Lead time | 20-30 days |

| Shipment port | Qingdao, China |

| Trade terms | FOB, CFR, CIF |

High quality raw materials

Application

Abrasive field

White fused alumina is a very high-quality abrasive material that can be made into different particle sizes for grinding and polishing materials such as metals, ceramics, glass, plastics, etc. It can greatly improve the surface smoothness of the processed material and meet the requirements for surface quality in different fields.

Optical field

White fused alumina has high transmittance, low coefficient of thermal expansion, excellent chemical and thermal stability, and is therefore widely used in the optical field. For example, it can be used to manufacture high-precision optical lenses, windows, prisms, and various optical devices.

Electronic field

White fused alumina also has important applications in the field of electronics. Due to its low conductivity, it can be used to manufacture high-temperature electrical insulation materials, such as high-temperature alumina ceramics, and is widely used in industries such as power electronics, communication electronics, aerospace, and automobiles.

Chemical industry

White fused alumina has excellent acid, alkali, and corrosion resistance properties, making it widely used in the chemical industry. For example, it can be used to manufacture highly corrosion-resistant equipment such as chemical reactors, pipelines, pumps, etc.

Factory display

Quality inspection equipment

Product catalogue

FAQ

Q1:Do you accept customized products?

A: Yes, we accept customized products, we can design and produce new products depend to your needs.

Q2:Do you supply samples?

A:Of course, we supply samples for your testing.

Q3:How about sample fee?

A: We provide free stock samples less than 1KG, if you need special samples, please contact us and we could communicate.

Q4:How can you ensure quality?

A: We will produce samples before mass production, and do final inspections before shipment.